Cosmetics,as we all know are skin-care products used to amplify the physical appearance of the human body,as in fair glow of the skin,eye-brows,eye-lashes,nails,lip-glows..etc.These cosmetics are made from chemical compounds derived from natural sources or they are synthetic.

Types

Setting Spray : to keep presence of applied makeup intact for a long periods of time.

Nail polish : used to color the fingernails and toenails.

Eyebrow pencils, creams, waxes, gels and powders are used to color and define the brows.

Eyeliner : used to amplify and elongate the size of the eye.

Mascara : used to darken, lengthen, thicken, or draw attention to the eyelashes.

Concealer : makeup used to cover any imperfections of the skin.

(source-http://yvhm.com/wp-content/uploads/2014/01/cosmetic-packaging-set-china-bottle-jar-244566.jpg)

Skin-care routines

Cleansers are generally applied to wet skin over the face and sometimes also the neck, avoiding the eyes and lips.

Face masks are treatments applied to the skin for a period of time, then removed. Typically, they are applied to a dry, cleansed face, avoiding the eyes and lips.

Exfoliants are products that help slough off dry, dead skin cells to improve the skin's appearance. This is achieved either by using acids or other chemicals to loosen old skin cells, or abrasive substances to physically scrub them off.

Toners are used after cleansing the skin to freshen it up and remove any traces of cleanser, mask or makeup, as well to help restore the skin's natural pH. They are usually applied to a cotton pad and wiped over the skin, but can also be sprayed onto the skin from a spray bottle.

The cosmetics packaging & packaging machinery market is intertwined with the developments in the overall cosmetic industry. Demand for creative and innovative cosmetic packaging is driving the cosmetic machinery market. The packaging is the first factor to attract the customer towards the product. Creative packaging attracts more customers, and also increases the shelf life of the product. The packaging type and raw material used for packaging is based on the type of cosmetic to be packed.

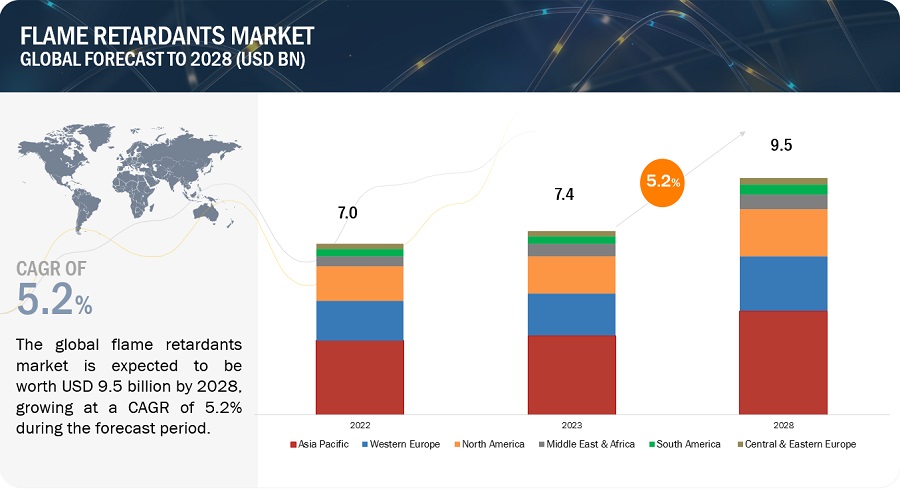

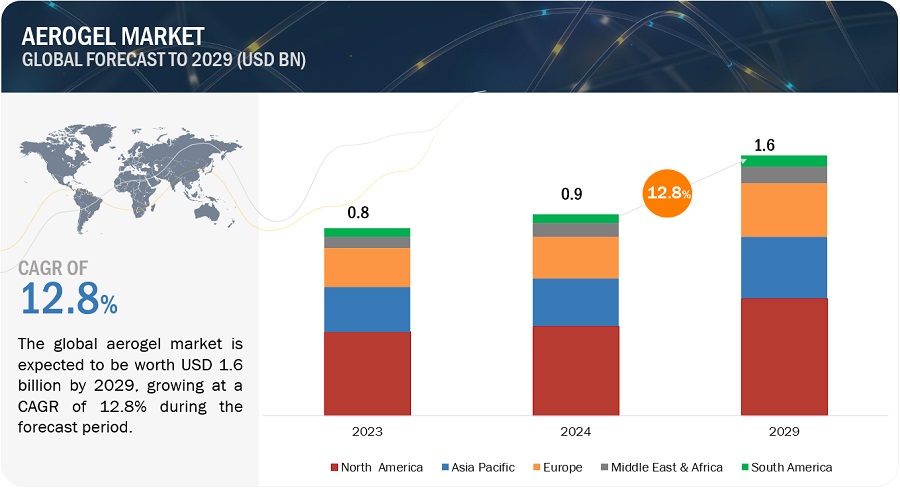

The global market value was $23,532.00 million in 2012 and is projected to reach $32,384.25 million by 2018, growing at a CAGR of 5.4% from 2013.

for more info,visit-