Can we use wind to generate power???...Oh yes we can!!....as we all are familiar of wind turbine which generate power(electricity) through their motors and fan motion due to heavy wind.A wind turbine is a device that converts kinetic energy from the wind into electrical power.

TYPES

TYPES

- Horizontal Axis Wind Turbine - A horizontal Axis Wind Turbine is the most common wind turbine design. In addition to being parallel to the ground, the axis of blade rotation is

parallel to the wind flow. - Up-Wind Turbines - Some wind turbines are designed to operate in an upwind mode (with the blades upwind of the tower).Large wind turbines use a motor-driven mechanism

that turns the machine in response to a wind direction. Smaller wind turbines use a tail vane to keep the blades facing into the wind. - Down-Wind Turbines - Other wind turbines operate in a downwind mode so that the wind passes the tower before striking the blades.Without a tail vane, the machine rotor naturally tracks the wind in a downwind mode.

- Shrouded Wind Turbines - The Savonius turbine is S-shaped if viewed from above. This drag-type VAWT turns relatively slowly, butyields a high torque. It is useful for grinding grains pumping water, and many other tasks, but its slow rotational speeds make it unsuitable for generating electricity on a large-scale.

Source - Google Image

Not all the energy of blowing wind can be harvested, since

conservation of mass requires that as much mass of air exits the turbine

as enters it. Betz' law

gives the maximal achievable extraction of wind power by a wind turbine

as 59% of the total kinetic energy of the air flowing through the

turbine.

Further inefficiencies, such as rotor blade friction and drag,

gearbox losses, generator and converter losses, reduce the power

delivered by a wind turbine. Commercial utility-connected turbines

deliver about 75% of the Betz limit of power extractable from the wind,

at rated operating speed.

Efficiency can decrease slightly over time due to wear. Analysis of

3128 wind turbines older than 10 years in Denmark showed that half of

the turbines had no decrease, while the other half saw a production

decrease of 1.2% per year.

The direct drive (gearless) wind turbine is the low-speed generator that eliminates the need for a gearbox from the turbine’s drive train. These turbines have advantages such as - these are lighter as compared to conventional turbine, these have significantly lower maintenance costs, and it is not needed to replace gearbox as these are gearless turbines. The most preferred direct drive wind turbine generator is the permanent magnet type generator, as it is lighter in weight and possesses high reliability for offshore applications.

Market Forecast

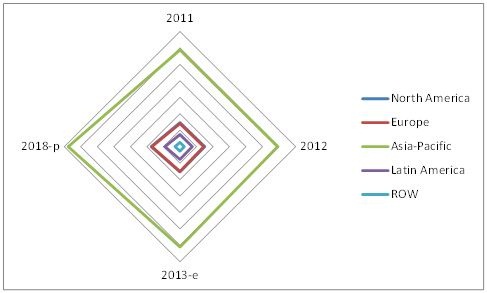

The global direct drive wind turbine market revenue is estimated to be $11.7 billion in 2011 which is estimated to reach $23 billion by 2017, at a CAGR of 15.2% from 2012 to 2017. In the global direct drive wind turbine, the permanent magnet synchronous generator captures the largest market at present share followed by electrically excited synchronous generator. The category 1 - 3 MW captures the largest market share followed by less than 1 MW and then above 3 MW.

For more info - http://www.marketsandmarkets.com/Market-Reports/direct-drive-gearless-wind-turbine-market-805.html